Calibration Package

At the heart of TMX Scientific’s thermal imaging devices lies the physics of thermoreflectance: a method of determining surface temperature changes by detecting minute variations of surface reflectivity. In order to transform the measured changes in temperature into absolute temperature results, the user must perform calibration.

In-Situ Calibration

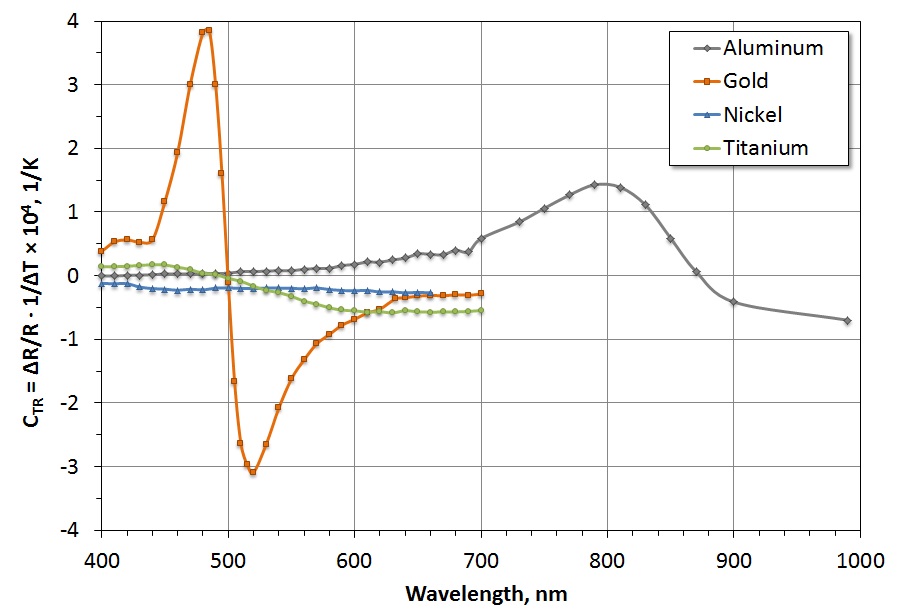

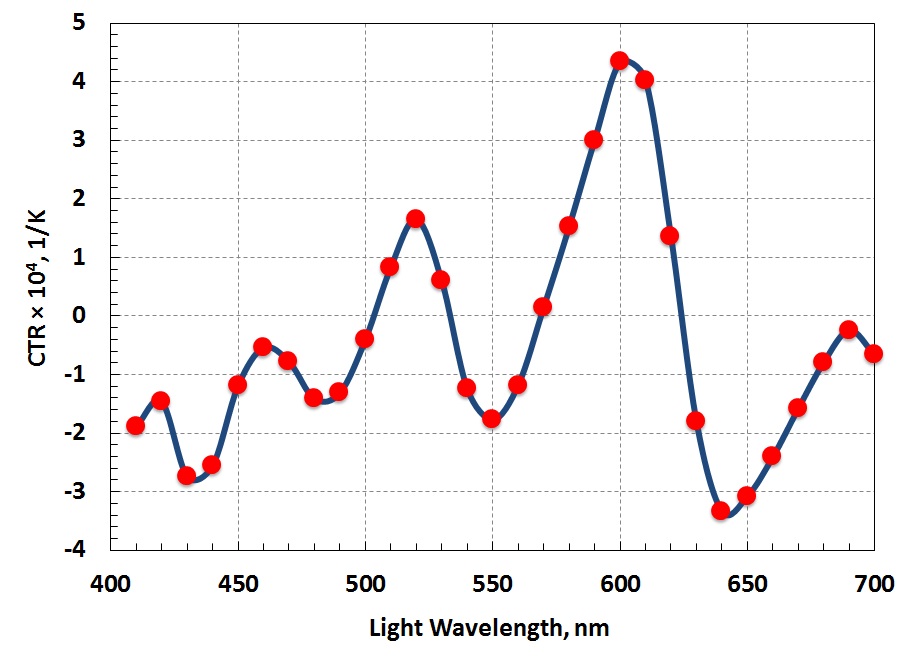

Thermoreflectance thermal imaging uses a relationship between a change in reflectivity and a change in surface temperature, which is known as the Coefficient of Thermoreflectance (CTR) and is derived from a calibration procedure. Through many years of testing and research, the TMX Scientific team has always stressed the critical dependence of CTR on a test setup. Factors such as the surface material composition, the wavelength of light, the passivation thickness, and the objective lens used during an experiment will affect the local CTR value. Due to the number of variables that can affect CTR, TMX Scientific strongly believes in performing in-situ calibration to obtain consistent, dependable results and to reduce uncertainty between experiments.

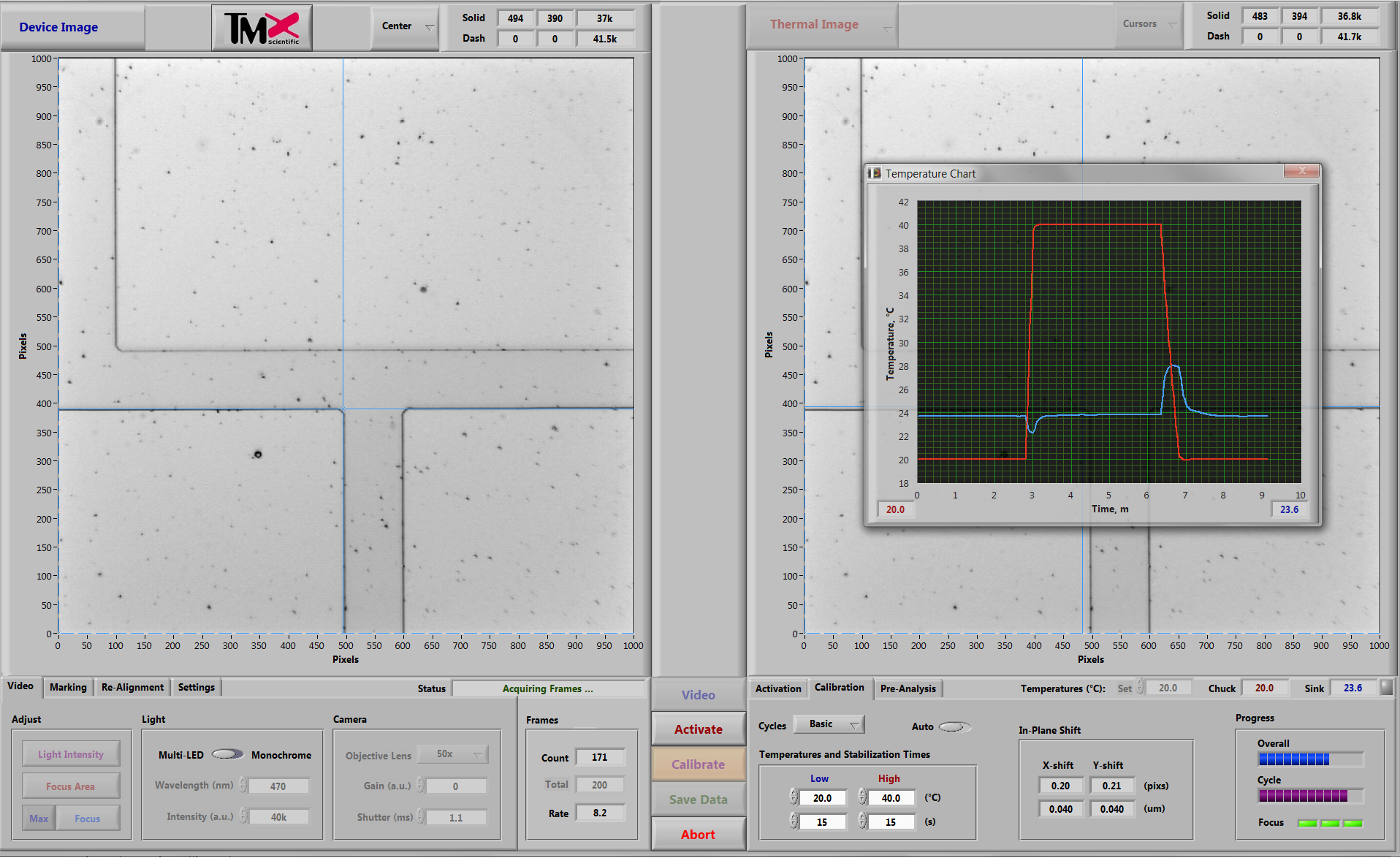

In-situ calibration begins with heating and cooling the device under test (DUT) to predefined values. Then, the system captures the DUT’s resulting surface reflectivity variations and derives the surface material’s CTR by relating the reflectivity changes to the known base temperature values. The

Results

TMX Scientific’s thermal imaging applications combine the calibration results with the device activation results and return the resulting temperature maps in straightforward, comprehensible formats. The

Calibration Base

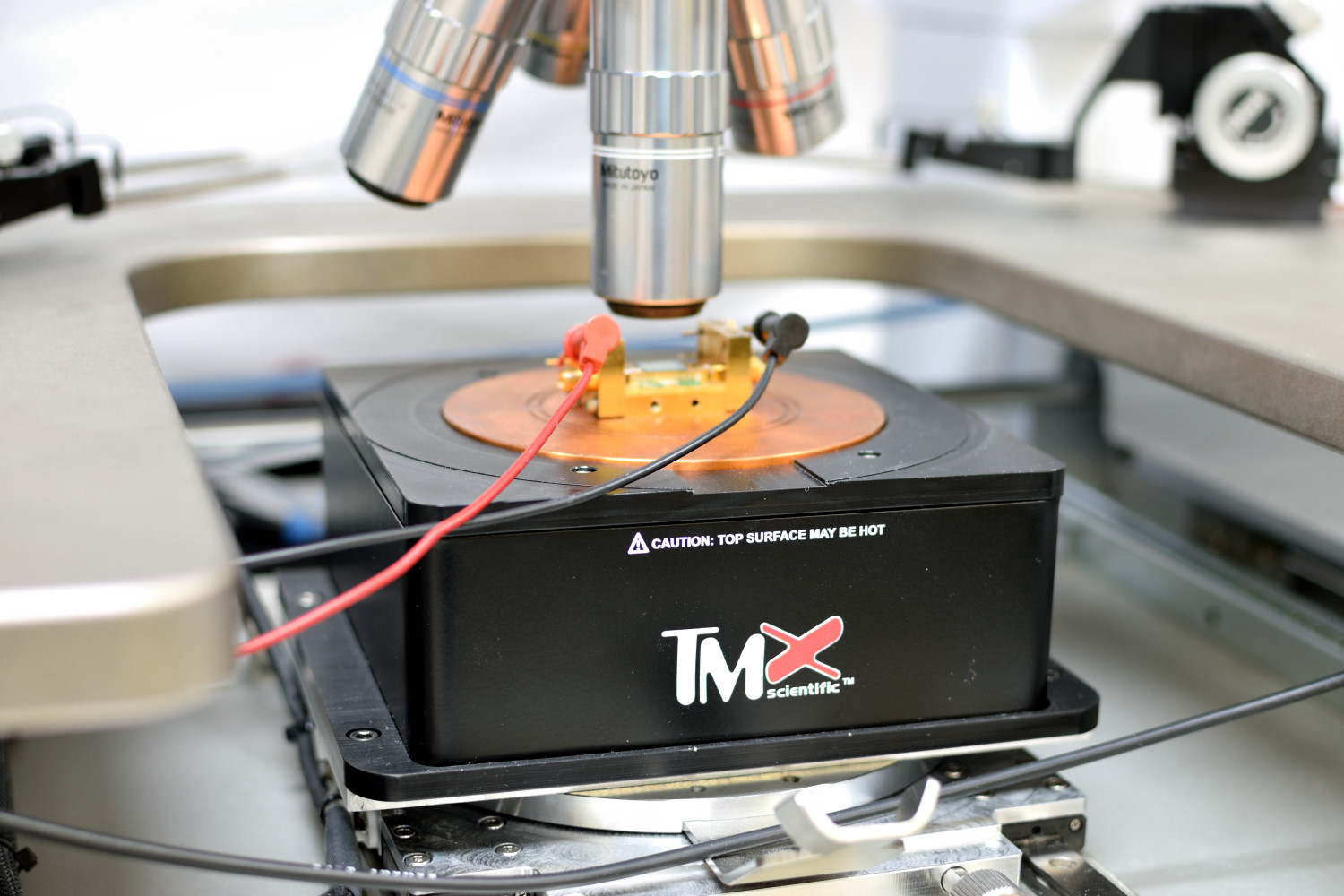

TMX Scientific’s Calibration Base (included with each Calibration Package) is a sample holder with vacuum capability and a copper alloy chuck that can be heated up to 100°C (212°F). The base assembly mounts to the user’s existing probe station (below the Measurement Head) and includes an adapter plate, if necessary. The Calibration Base’s heat sink temperature is regulated by a liquid chiller unit (included) and is monitored by the

Dynamic Tracking and Alignment

Since TMX Scientific applications compare sets of thermal images at deep submicron resolution, TMX Scientific utilizes both hardware and software corrections to ensure the thermal images align with absolute accuracy.

Each Calibration Base is equipped with dynamic tracking capability to correct any movement in the X-, Y-, and Z-directions caused by thermal expansion during a calibration procedure. The

To correct DUT shifting during calibration, the

The Power of Nanoscale Calibration

Preserving similarities between calibration and activation procedures reduces the uncertainty within subsequent thermal images. By combining physical calibration procedures with software-derived calibration formulas,

Benefits

- Superior accuracy with in-situ calibration

- Dynamic tracking corrects up to 2 nanometers (7.9E-8 in.) of movement in each direction

- Turn-key operation

- Modular Design

- Novel pixel-by-pixel calibration (with

T°Pixel ) - Nanoscale alignment

Applications

- Obtain absolute surface temperature maps

- Locate hot spots and measure amplitude at device level